Russian Lathe Accident: What You Need To Know

Hey there, friend! Ever heard of a Russian lathe accident? Yeah, it’s one of those topics that’s both fascinating and a little scary at the same time. If you’re into machining or just curious about industrial mishaps, this is the perfect place to dive in. We’re gonna break it down for you—what it is, why it happens, and most importantly, how to avoid it. So, buckle up, because we’re about to get into the nitty-gritty details!

Imagine this: you’re working in a machine shop, all focused on crafting precision parts with a lathe. Suddenly, something goes wrong, and before you know it, there’s an accident. Russian lathe accidents are no joke—they can be dangerous and costly. But don’t worry, we’re here to help you understand what causes them and how to stay safe.

Now, if you’re thinking, “Why should I care about Russian lathes?”—well, it’s simple. Whether you’re a professional machinist or just someone who’s curious about machinery, knowing about these accidents can save you from potential trouble. And trust me, nobody wants to deal with a lathe gone rogue. Let’s dig deeper, shall we?

- The Avett Brothers Explore Their Music Infectious Melodies

- Bridget Fonda Updates News What You Need To Know Now

Table of Contents

- What is a Russian Lathe?

- Common Causes of Russian Lathe Accidents

- Safety Tips for Preventing Accidents

- Brief History of Russian Lathes

- Accident Statistics

- Importance of Maintenance

- The Role of Training

- Responsibility of the Machinist

- How Modern Technology Helps

- Conclusion

What is a Russian Lathe?

A Russian lathe, like any other lathe, is a machine used for shaping metal or wood by rotating the material on its axis. But what makes Russian lathes special? Well, they’re known for their robust build and reliability, especially in heavy-duty applications. However, with great power comes great responsibility, right? That’s where accidents can happen if things aren’t handled properly.

Now, Russian lathes aren’t inherently dangerous. It’s more about how they’re used. Think of it like driving a car—if you don’t follow the rules, you’re asking for trouble. Same goes for operating a lathe. So, let’s talk about what can go wrong and why.

Why Russian Lathes Stand Out

There’s something unique about Russian lathes—they’re built to last. These machines are designed for industrial use, meaning they can handle some serious workloads. But here’s the kicker: their durability can sometimes give operators a false sense of security. Just because the machine is tough doesn’t mean you can slack off on safety protocols.

- Explore Loretta Swit Movies Tv Shows Where To Watch Now

- Knox Joliepitt Facts The Girl Rumor You Need To Know

Here’s a quick rundown of what makes Russian lathes different:

- Heavy-duty construction

- High precision capabilities

- Great for large-scale projects

Common Causes of Russian Lathe Accidents

Alright, let’s get real for a second. Accidents happen, and when it comes to lathes, there are a few common culprits. Whether it’s human error or equipment malfunction, knowing the causes is the first step to preventing them. Here’s a look at what typically goes wrong:

Human Error

Let’s face it—we’re all human, and mistakes happen. Sometimes, it’s as simple as not paying attention or skipping a safety step. Other times, it’s a lack of training or experience. Whatever the reason, human error is one of the leading causes of lathe accidents.

For example:

- Not wearing proper safety gear

- Improper setup of the machine

- Overlooking maintenance checks

Equipment Malfunction

Even the best machines can have a bad day. Over time, wear and tear can lead to breakdowns or malfunctions. That’s why regular maintenance is so important. If a lathe isn’t properly cared for, it’s more likely to cause problems.

Some common issues include:

- Worn-out bearings

- Loose parts

- Electrical failures

Safety Tips for Preventing Accidents

Now that we know what can go wrong, let’s talk about how to keep things running smoothly. Safety should always be your top priority when working with machinery. Here are some tips to help you stay safe:

Wear the Right Gear

Protective equipment is your best friend in the workshop. Whether it’s safety glasses, gloves, or earplugs, make sure you’re equipped before you start working. It might seem like a hassle, but trust me, it’s worth it.

Follow the Manual

Every machine comes with a manual for a reason. Take the time to read it and understand how your lathe works. It’s like the rulebook for success—don’t ignore it!

Stay Focused

Distractions can be deadly in a machine shop. Keep your mind on the task at hand and avoid multitasking. It’s not just about getting the job done; it’s about doing it safely.

Brief History of Russian Lathes

Before we dive deeper into the nitty-gritty of accidents, let’s take a quick trip back in time. Russian lathes have a rich history, dating back to the early days of industrialization. They were designed to meet the demands of heavy industry, and their reputation for durability has stood the test of time.

Here’s a quick look at some key milestones:

- Development in the Soviet era

- Adaptation for modern use

- Influence on global machining

Biographical Table

| Feature | Details |

|---|---|

| Origin | Russia/Soviet Union |

| Primary Use | Industrial machining |

| Notable Models | Rostselmash, Kalashnikov |

Accident Statistics

Let’s talk numbers for a second. According to recent studies, lathe accidents account for a significant portion of workplace injuries in the machining industry. While exact figures vary, one thing is clear: these accidents are preventable with the right precautions.

Here are some stats to consider:

- Approximately 10% of machining injuries involve lathes

- Most accidents occur due to human error

- Regular maintenance reduces risk by 50%

Importance of Maintenance

Maintenance is like the unsung hero of machinery. Sure, it might not seem glamorous, but it’s crucial for keeping your lathe running smoothly. Regular checks can catch potential problems before they become disasters.

What to Check

Here’s a quick checklist for maintaining your Russian lathe:

- Bearings and gears

- Electrical connections

- Coolant levels

The Role of Training

Training is another key factor in preventing accidents. Whether you’re a seasoned pro or a newbie, ongoing education is essential. The more you know, the safer you’ll be.

Training Tips

Here’s how to get the most out of your training:

- Take hands-on courses

- Practice with supervision

- Stay updated on industry trends

Responsibility of the Machinist

At the end of the day, the machinist is the one operating the machine. That means they have a big responsibility to ensure safety. From following protocols to reporting issues, every step counts.

Key Responsibilities

Here’s what a machinist should do:

- Inspect the machine before use

- Report any malfunctions immediately

- Stay informed about safety regulations

How Modern Technology Helps

Technology has come a long way, and it’s making a big difference in the world of machining. From advanced safety features to real-time monitoring, there are plenty of tools to help prevent accidents.

Examples of Modern Tech

Check out these innovations:

- Sensor-based safety systems

- Automated maintenance alerts

- Virtual reality training programs

Conclusion

Alright, we’ve covered a lot of ground here. From understanding what Russian lathe accidents are to learning how to prevent them, you’re now armed with the knowledge to stay safe in the workshop. Remember, safety is everyone’s responsibility, and with the right precautions, you can avoid potential disasters.

So, what’s next? Take action! Whether it’s investing in training, performing regular maintenance, or just wearing your safety gear, every step counts. And don’t forget to share this article with your fellow machinists. Knowledge is power, and together, we can make the workplace safer for everyone.

Oh, and one last thing—leave a comment below and let us know what you think. We’d love to hear your thoughts on Russian lathe accidents and how we can keep improving safety in the industry. Thanks for reading, and stay safe out there!

- Unlocking Onlyfans Your Guide To Onlyfinder Original More

- Sean Duffy Height Age More Facts You Need To Know

Smoke Rises After Explosion at Russian Warehouse The New York Times

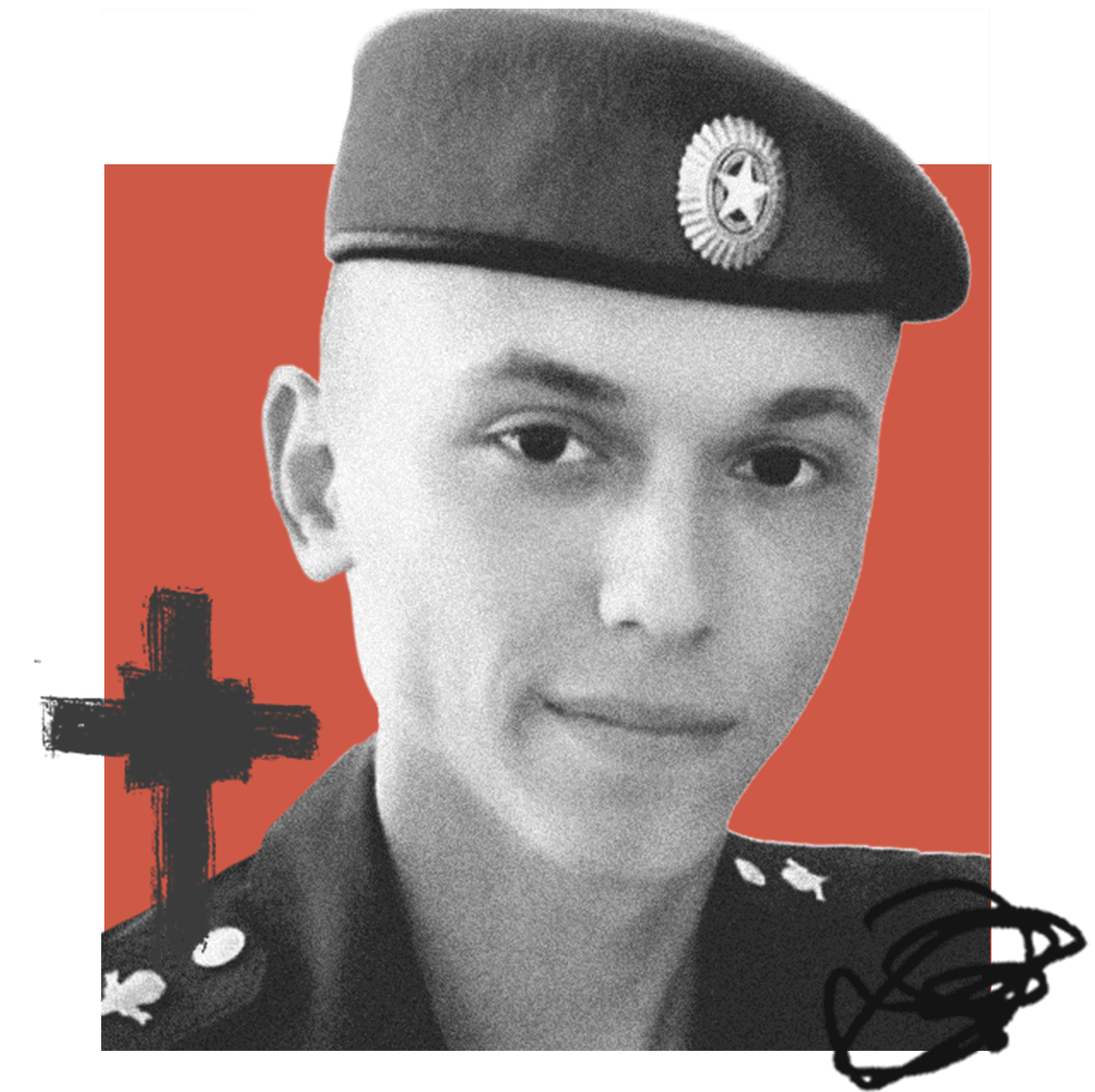

Counting Russia's dead in Ukraine and what it says about the changing

Russian Lathe Accident Reddit